Liquifire #621, Part II, Take III

-

DeereKid9

- Posts: 1172

- Joined: Wed Jan 31, 2007 1:00 am

- Real Name: Bob Amber

- Location: Churubusco Indiana

Re: Liquifire #621, Part II, Take III

And, your tunnel protectors are backward. You have them end for end.

Sent from my SPH-L710 using Tapatalk

Sent from my SPH-L710 using Tapatalk

Always remember-Any parts leftover is money in your pocket.

1976 Liquidator - I 500 raced by Jim Zimmer

1980 Spitfire

1982 Liquifire-Last sled my son helped me work on. He did most of the motor work.

1984 Trailfire

2007 Ski Doo GSX 500SS

1976 Liquidator - I 500 raced by Jim Zimmer

1980 Spitfire

1982 Liquifire-Last sled my son helped me work on. He did most of the motor work.

1984 Trailfire

2007 Ski Doo GSX 500SS

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

Grumpy,

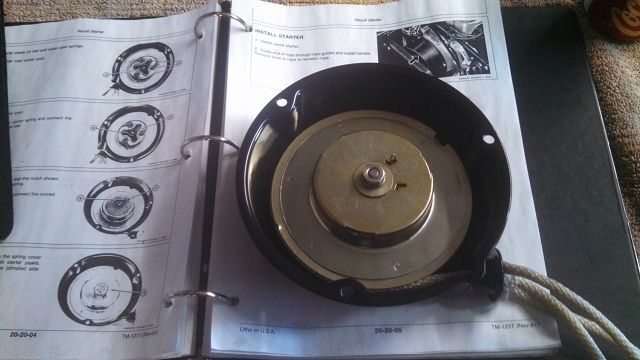

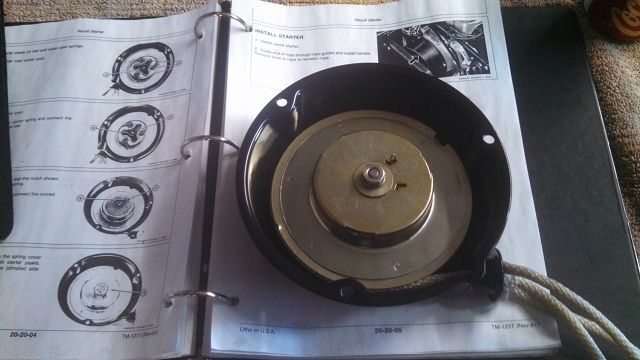

Thank you for pointing out that I did not have all 3 of the pawl return springs installed, but the pic was taken during the rebuilding process. No worries, all three were properly installed before finishing the recoil:

I then had to call in Grumpy's favorate groupie, Cari Deerest, to lend a hand flipping the chassis over:

I hope to have the chassis basically complete before Kudla visits 2 1/2 weeks. Might need his help to safely get this thing off the saw horses...

Thank you for pointing out that I did not have all 3 of the pawl return springs installed, but the pic was taken during the rebuilding process. No worries, all three were properly installed before finishing the recoil:

I then had to call in Grumpy's favorate groupie, Cari Deerest, to lend a hand flipping the chassis over:

I hope to have the chassis basically complete before Kudla visits 2 1/2 weeks. Might need his help to safely get this thing off the saw horses...

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- 80spitfire

- Posts: 804

- Joined: Tue Aug 31, 2010 6:59 pm

- Real Name: Brian Kottke

- Location: Southern Minnesota

Re: Liquifire #621, Part II, Take III

Looking great Joe! I too hope to see you finish this race before Kenny kicks the proverbial bucket! lol

-Brian

-Brian

72' 500 Restored

74' 295/S Unrestored

75' 340/S Rider

76' Liquidator Restored

77' Liquifire Rider

80' Spitfire Restored

74' 295/S Unrestored

75' 340/S Rider

76' Liquidator Restored

77' Liquifire Rider

80' Spitfire Restored

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

Thanks Brian. I am also trying to make the sled a little more crash tolerant this year, and will do a better job securing all the fuel lines too.

...and back to our story, already in progress...

With the chassis upside down, I put a moving blanket across the tunnel to keep the studs from scratching the shiny black finish:

I used an empty tub to hold the track up while I installed the drive axle with all the bearings, flanges, etc:

...and back to our story, already in progress...

With the chassis upside down, I put a moving blanket across the tunnel to keep the studs from scratching the shiny black finish:

I used an empty tub to hold the track up while I installed the drive axle with all the bearings, flanges, etc:

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

This step reminds me how much a pain it can be to remember the proper order of installation of the drive axle. On the chaincase side, you first have the cork gasket, outer bearing flang, bearing with an o-ring, outer flange, then the aluminum spacer. The bolts come in from the chaincase side:

Getting the bottom nut and washer on is a little tricky, but not too bad.

On the clutch side of the sled, the aluminum spacer goes between the bearing flanges and the chassis. The retaining bolts go from the inside of the tunnel out toward the speedo drive. The top one can be tricky to install, so I insert the bolt partly in and rotate the bearing assembly, and then put the last two in. Then a screw driver can be used to push them home.

Next up is re-assembling the suspension after correcting a few small issues I found:

Getting the bottom nut and washer on is a little tricky, but not too bad.

On the clutch side of the sled, the aluminum spacer goes between the bearing flanges and the chassis. The retaining bolts go from the inside of the tunnel out toward the speedo drive. The top one can be tricky to install, so I insert the bolt partly in and rotate the bearing assembly, and then put the last two in. Then a screw driver can be used to push them home.

Next up is re-assembling the suspension after correcting a few small issues I found:

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- JDXspec

- Posts: 896

- Joined: Thu Jul 21, 2005 12:00 am

- Real Name: Dustin

- Location: SW Minnesota

- Contact:

Re: Liquifire #621, Part II, Take III

Have you learned Nothing from the factory racers? weld your nuts to the bearing flange! Makes it easier to install the drive shaftGetting the bottom nut and washer on is a little tricky, but not too bad.

Own 74 295/s, 75 340/S, 800, 76 440 Liquifire, 300, Liquidator (3), 78 440 Liquifire, 340 Liquifire CC, 80 Liquifire, 82 Trailfire LX, 83 Sprintfire 84 Sportfire

-

ICCSF 108

- Posts: 4369

- Joined: Sun Jul 17, 2005 12:00 am

- Real Name: Kenny Heins, AKA Grumpy

- Location: Blue Springs Mo.

- Contact:

Re: Liquifire #621, Part II, Take III

Grumpy

AKA: Kenny, Grumpy, Mr. Richard Head

"I Hunt For it, Purchase it, Haul it, Sometimes Repair it, Sometimes Break it, Then Fix it Again, Label it, Warehouse it, Talk About it, So NOW, HOW Can I Take Any Less $$ For It?"

"God I love the smell of KLOTZ in the morning, That smell, you know that Gasoline/Oil Smell, MAKES the whole place SMELL like.. LIKE VICTORY. You know someday the 2 strokers are gonna end..."

Do Anti-War Protesters have reunions? If so what do they TALK about?

"I Hunt For it, Purchase it, Haul it, Sometimes Repair it, Sometimes Break it, Then Fix it Again, Label it, Warehouse it, Talk About it, So NOW, HOW Can I Take Any Less $$ For It?"

"God I love the smell of KLOTZ in the morning, That smell, you know that Gasoline/Oil Smell, MAKES the whole place SMELL like.. LIKE VICTORY. You know someday the 2 strokers are gonna end..."

Do Anti-War Protesters have reunions? If so what do they TALK about?

-

Matt

- Posts: 4747

- Joined: Wed Jul 13, 2005 12:00 am

- Real Name: Matt

- Location: Coopersburg, PA

- Contact:

Re: Liquifire #621, Part II, Take III

Extra parts are just a bonus.ICCSF 108 wrote:I won't mention the extra part..

can't believe knowone else saw it??

Grumpy

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

Grumpy, you do in fact see an extra part from stock.ICCSF 108 wrote:I won't mention the extra part...

Grumpy

I use an extra aluminum spacer from the speedo drive end of the drive shaft to beef up the chaincase lower bearing mounts. Adding the aluminum spacer holds the flanges in compression to the chain case. The result is a stronger assembly and flanges that don't bend. This does prevent you from welding nuts onto the flanges to ease assembly, but it make the driveshaft assembly more tollerant to rock hits for a very small weight penalty.

I have reinforced several area's of the sled besides this, including adding 2 more rear axle wheels, larger tie rod ends, with a steel tie rod, installing a front skid plate and chaincase guard, grade 8 bolts, etc, to make sure the sled can handle rock/tree hits better than last year...

Even with all this damage, the sled still finished the 150 mile VC a week after the I-500.

Later Liquidator,

-Joe

Last edited by JoeRainville on Mon Nov 25, 2013 2:44 pm, edited 1 time in total.

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

While I have been working on some of the small suspension issues, I also needed to do something with the front bumper. I had a few other bumpers, but I also wanted to try to straighten the crumpled one. What started out looking like this:

With some heat, blocks of wood and a 3 lbs hammer ended up looking better. Not quiet good enough for a restoration, but OK for a race sled. This was also practice for straightening out the other 3 bumpers that had smaller, but noticable issues.

With some heat, blocks of wood and a 3 lbs hammer ended up looking better. Not quiet good enough for a restoration, but OK for a race sled. This was also practice for straightening out the other 3 bumpers that had smaller, but noticable issues.

Last edited by JoeRainville on Thu Nov 21, 2013 1:56 pm, edited 4 times in total.

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

Since I had several bumpers to work on this weekend, including three from 80-84 Liquifires and one from a 340/s, I figured I would try Brock's method of removing decals. Instead of decal & adhesive remover and scraping, I applied heat to the back side of each bumper:

And pulled the tape right off, including most of the adhesive:

And pulled the tape right off, including most of the adhesive:

Last edited by JoeRainville on Mon Nov 18, 2013 9:04 pm, edited 1 time in total.

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

After sandblasting the old coating off, three bumpers were dropped off for powder coating:

They should be ready to pick up on Friday, the 22nd. I also have some help driving in for the weekend. Tim Kudla is stopping down for the weekend, and has offered to help wrench on my many projects. Great to have friends visit, better when they lend a hand

-Joe

They should be ready to pick up on Friday, the 22nd. I also have some help driving in for the weekend. Tim Kudla is stopping down for the weekend, and has offered to help wrench on my many projects. Great to have friends visit, better when they lend a hand

-Joe

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

Kudla showed up Friday night (Nov 22nd) for the weekend. So, being the nice guy that I am, put him to work on the Liqufire. It took both of us to wrestle the front bumper into place, good thing I had help:

The final product didn't come out too bad, considering that is the same bumper I mangled in the VC:

The final product didn't come out too bad, considering that is the same bumper I mangled in the VC:

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.

- JoeRainville

- Posts: 4355

- Joined: Tue Aug 02, 2005 12:00 am

- Real Name: "John Deere Joe"

- Location: Fort Worth, Texas

- Contact:

Re: Liquifire #621, Part II, Take III

The rear skid was pretty straight forward, basically just a re-assembly job and a few small fixes. The arms looked good after powder coating, but the one issue I have with that process is that it tends to fill in holes and make them smaller. Tim tried to clean the top front shock bolt out with the drill, but I ended up having to use good old sand paper:

The finished skid looks like it has more updates that it really does. For the first Vintage I-500 back in 2011 we added a front coil over shock, a Carver custom build rear shock, a 4 idler wheel set up for the rear axle, and for last year I installed a "Watersboy special" modified front idler kit. The original cross shaft would have hit the front shock, so Kenny separated the mounts. Other than that, she is all Deere:

After looking at it, I should have had the slide rails powder coated too, but it's November already...

The finished skid looks like it has more updates that it really does. For the first Vintage I-500 back in 2011 we added a front coil over shock, a Carver custom build rear shock, a 4 idler wheel set up for the rear axle, and for last year I installed a "Watersboy special" modified front idler kit. The original cross shaft would have hit the front shock, so Kenny separated the mounts. Other than that, she is all Deere:

After looking at it, I should have had the slide rails powder coated too, but it's November already...

Last edited by JoeRainville on Tue Nov 26, 2013 8:53 pm, edited 1 time in total.

Honorary Tech Editor

Chuck Norris doesn't get frost bite. He bites the frost.

Chuck Norris doesn't get frost bite. He bites the frost.