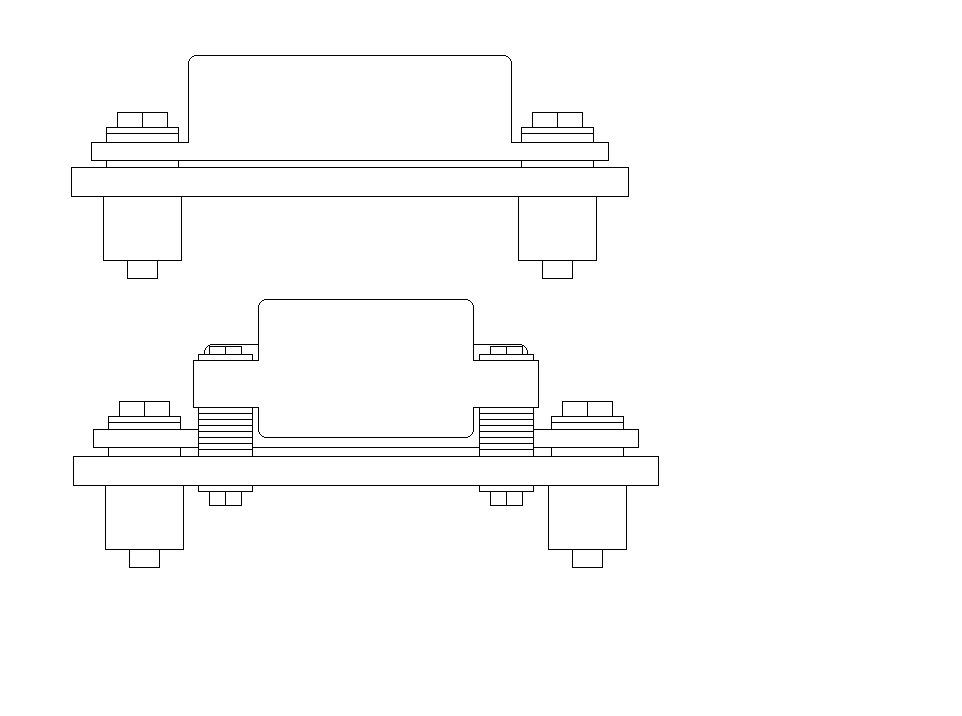

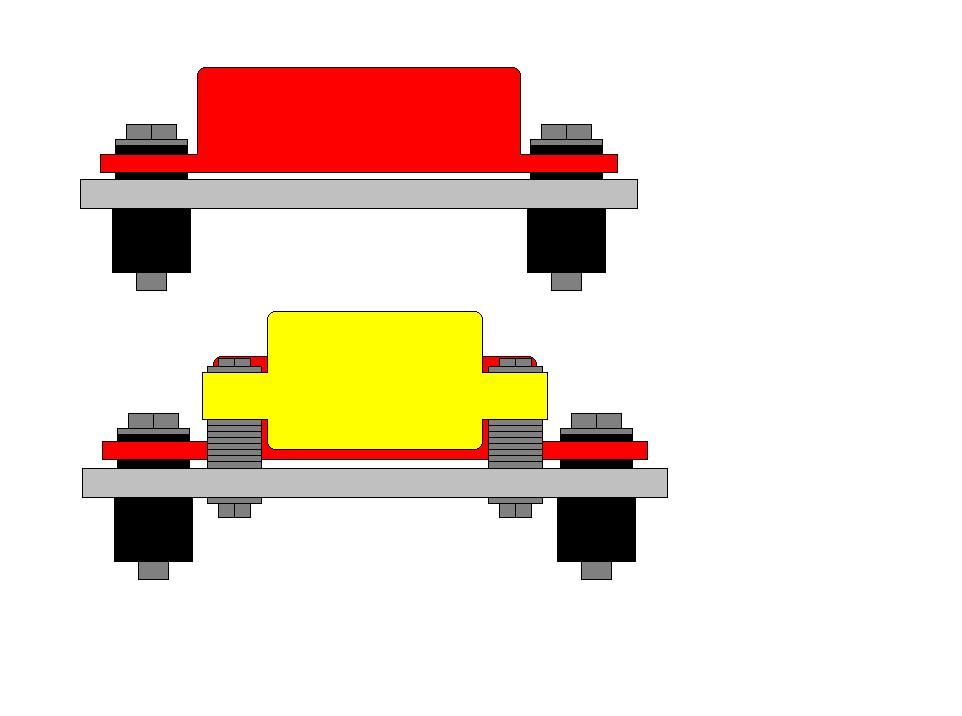

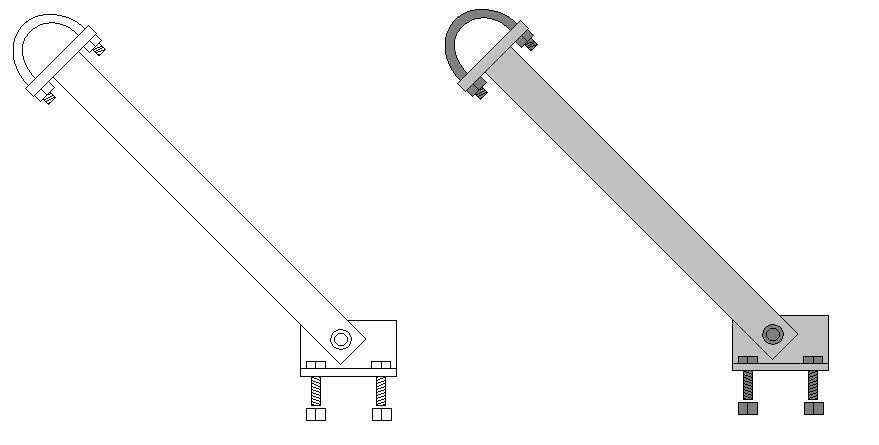

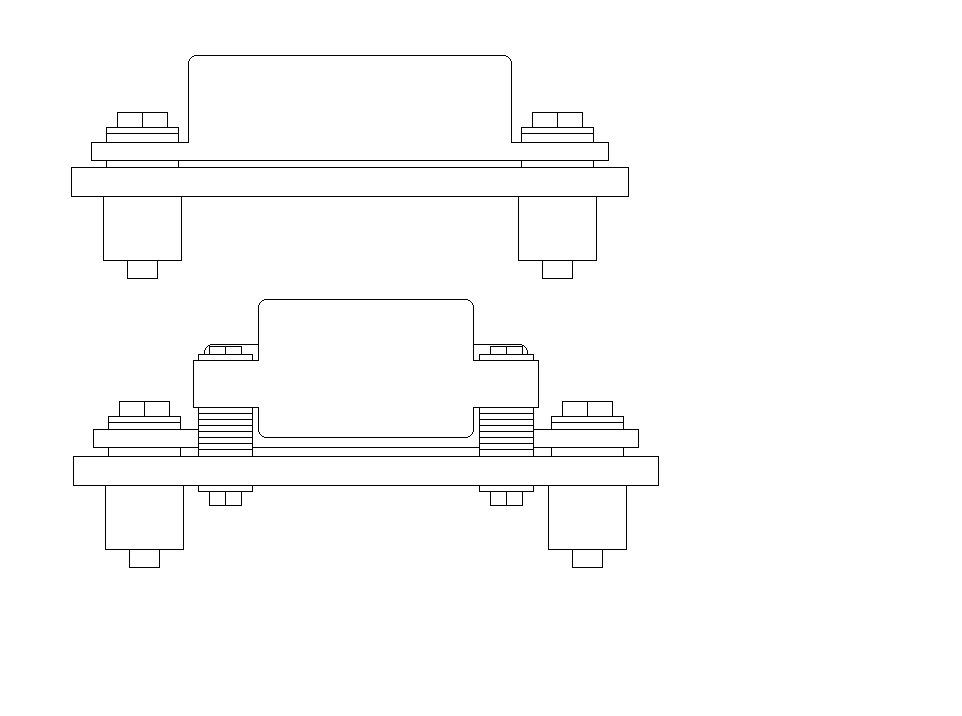

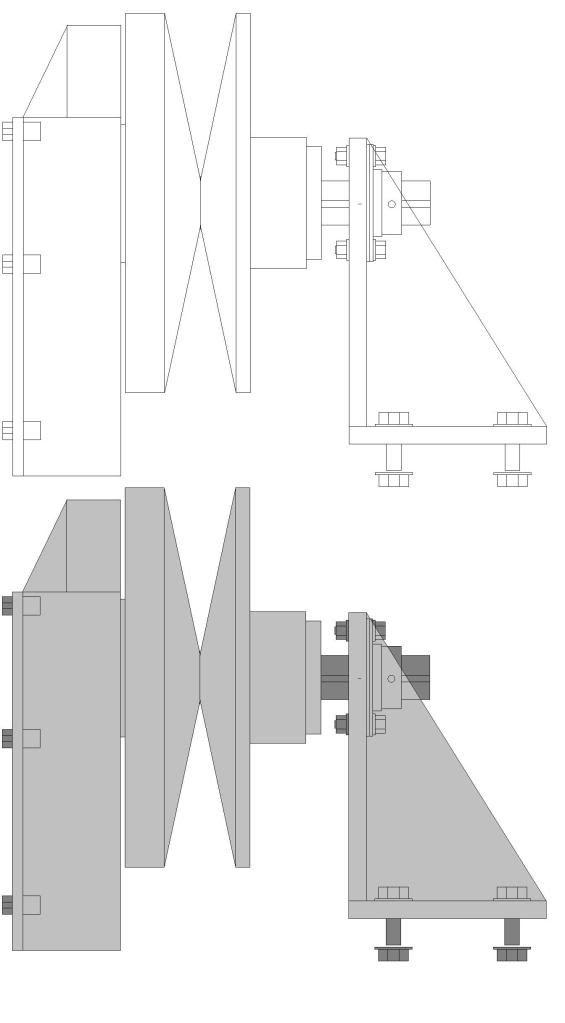

the short jack shaft idea does make sense and I'm sure it would keep the top of the chain case assembly from twisting from either way, would it be better to use a pillow block bearing, on a bearing tower similar to that of a speedway, or build a bracket that has one of those 3 bolt bearing flanges like you would on a drive axle assembly, making it outta some 3/8" alum that mounted to the tunnel then supported down to the bulk head and to the motor mount.

i will have to look around the garage and see what i have for a jack shaft that i can cut down to make it work that has the correct size splines, O.D etc... then i can cut it down to the correct length needed and some even have a long key way on them.

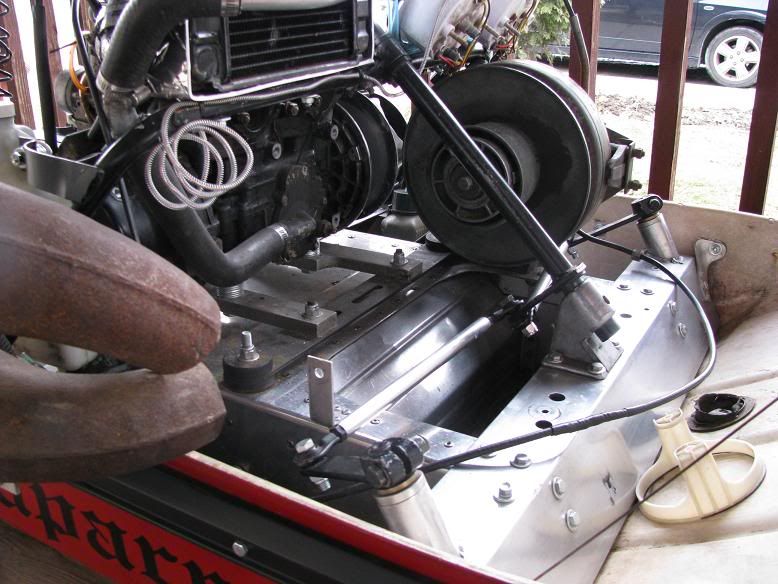

as far as the zip ties, i just have them on there temporarily to hold the tank, that way i can pull it when needed to hook up the lines etc.... i am planning on going with some SS hose clamps I'm sure that they make them large enough that would wrap around the tank and mounting bracket then i can hide the adjustment screw under the tank bracket for a ice clean look.

i got talking to a guy that is pretty knowledgeable about cats, and he suggested that i could bypass the oil injection system by making it a closed loop system so i could run premix.

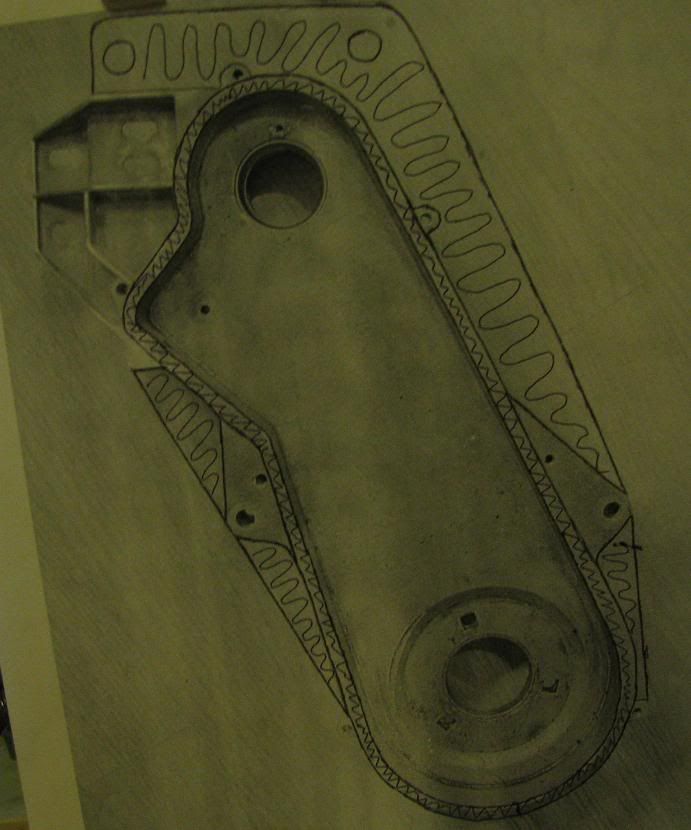

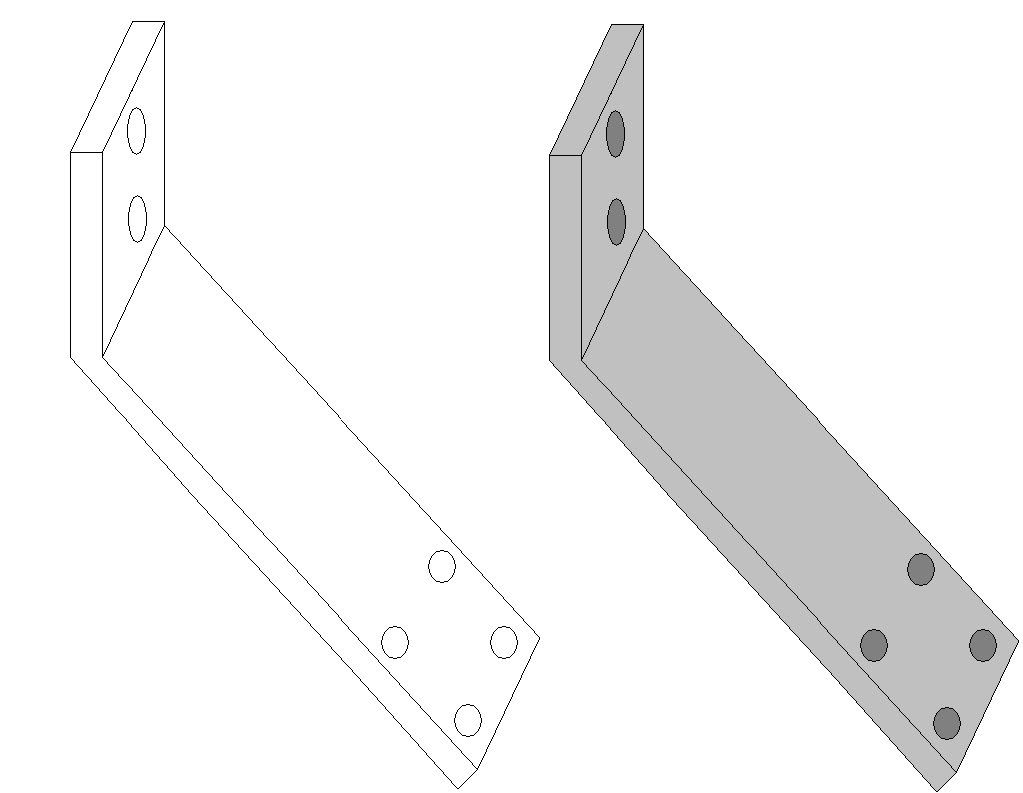

its funny that you say that about the ign. coil and the cdi box because i got thinking of a way to make it look better and not hacked up, i drew up a bracket that's made outta the same alum diamond plate that allows the cdi box to be mounted in the stock holes on the recoil housing, the bolts that go down through the cdi box and into the mounts on the recoil would hold the alum diamond plate as well, and the ignition coil i am planning on mounting to the plate between the cdi box, and the slide rail lube tank to give it a cleaner look

thanks, i really enjoy the challenges of building a sled like this because it allows me to incorporate different idea's thinking of different ways how it could be built. And how to make it all come together and look presentable as well